Gernal

Avoiding Costly Mistakes: A Scientific Guide to Selecting the Best Material for Your Custom Gear Systems

Introduction

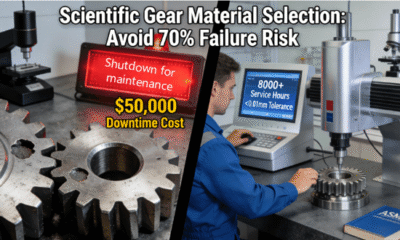

In the area of mechanical engineering, experts are generally confronted with the classic trade-off problem when designing custom gear systems: either selecting high-strength wear-resistant materials will result in extremely high costs and complicated machining processes, or selecting cost-effective materials may cause early failure under severe operating conditions, leading to substantial downtime and lost production. The problem essentially arises from conventional material selection procedures, which excessively rely on empirical equations and reference books, without conducting a comprehensive analysis of the actual operating conditions, such as impact loading, temperature, and lubrication conditions. This commonly causes either over-engineering or under-designing. Based on two decades of precision manufacturing expertise, this article introduces a scientific material selection procedure that systematically considers the interplay of operating conditions, material properties (such as fatigue strength and hardness), and cost-effectiveness.

With this guide, experts can make optimal decisions that simultaneously consider performance, lifetime, and costs. The subsequent sections will break down the entire procedure for scientific material selection.

How to Systematically Evaluate Operating Conditions to Determine Core Material Needs for Gears?

Accurate diagnosis of operating conditions is the first step towards scientific material selection. This ensures that the material is perfectly suited to the operating conditions of the gear, avoiding over-specification and under-specification.

1. Analyzing Key Operational Parameters

The first step in material selection is to identify and quantify various parameters, which include torque, speed, type of load (constant or impact), temperature, lubricating conditions, and corrosive conditions. For example, high-torque conditions require materials with high yield strength, whereas variable conditions require materials with high fatigue strength. The list of parameters is exhaustive and serves as the basis for all other decisions.

Linking Parameters to Material Property Requirements

As discussed, each of these parameters plays a vital role in the determination of the properties that the materials should exhibit. For example, high temperatures require materials with high thermal stability so that the materials do not soften. Additionally, low lubrication environments require materials with inherent lubricity or the ability to be made lubricant compatible. In other instances, exposure to corrosive substances requires materials with improved corrosion resistance.

Leveraging Authoritative Standards and References

One of the ways to make your content more credible is to provide citations from publications that are considered highly reliable sources. For example, the ASM Handbook is a great reference that provides detailed criteria of how different materials behave in various service environments. In the surface gear machining services material selection guide, the authors thoroughly examine the interplay of fatigue life, hardness, and microstructure. The readers can treat this piece of information as a clue for further investigation. Also, the engineer could consult other resources if he wants to delve into the study of extreme condition analysis.

What Are the Common Gear Materials and Their Performance in Typical Applications?

Simply put, there are no best materials in gear manufacture. In fact, the best material is the one whose properties are best suited for the particular application. This chapter will review the most popular materials for gears and compare their performance and most suitable applications.

Metallic Alloys: Strength and Durability

Alloy steels, for example, 4140 and 4340, are well-known for their high strength-to-weight ratios and good hardenability. These materials have been used for automotive transmission and machine component gears. Another example is case-hardening steels, like 20CrMnTi, which have a hard surface for wear resistance and a tough core for impact resistance.

Non-Metallic Options: Lightweight and Corrosion Resistance

Nylon and POM are engineering plastics that have various benefits, such as lightweight operation, noise reduction, and natural corrosion resistance. These materials are best suited for food processing equipment, domestic appliances, and applications where weight reduction is of utmost importance. On the other hand, bronze alloys are selected based on their wear resistance and compatibility with steel parts, commonly used in worm gears and bushes.

Making the Right Choice for Your Scenario

The choice of materials should be guided by the requirements of the application rather than by the relative ranking of materials only. In aerospace applications, where it is very important to save weight and to ensure reliability, high, strength steels or titanium alloys are used even though their price is higher. Whereas, for low, speed, non, critical applications, cast iron or plastics make good substitutes. By comparing the strength, hardness, cost, and machinability, one can limit the options.

How Do Heat Treatment and Surface Treatments Significantly Enhance Gear Performance and Lifespan?

Although the choice of the base material is a factor, one should also pay equal attention to the post, processing methods that significantly improve the performance and the durability of the gear parts.

l Core Enhancement Through Heat Treatment: Heat treatments such as carburizing, quenching and tempering, and induction hardening are the main methods that can be used to improve the properties of gear components. Carburizing, for instance, involves adding carbon to the surface of the gear component thereby greatly increasing its hardness and wear resistance, while the core still remains soft enough to absorb shocks and impacts. It is especially important that gear parts have both a hardened surface and a ductile core when they are subjected to repeated contact stress. Gear load capacity can be significantly increased if materials are properly heat treated to raise their fatigue strength as evidenced by the ISO 6336 standard which associates the quality of heat treatment to gear load capacity.

l Surface Engineering for Superior Performance: Surface engineering comprises nitriding and Diamond, Like Carbon (DLC) coating which impart an extra layer of defense. Nitriding produces a hard and corrosion, resistant surface layer with minimum distortion which is ideal for making gears with very precise dimensions that require tight tolerances. A DLC layer is also a very good option for reducing friction and wear, especially under conditions of poor lubrication. Both of these processes are widely utilized in the automotive and aerospace sectors in order to achieve performance standards that are better than ever.

l Ensuring Consistency Through Quality Controls: In demanding industries, following quality management systems such as ISO 9001 and IATF 16949 very closely can allow heat treatment processes to become not only precisely controlled but also consistent. This is very important both for attaining the global standards and for delivering the performance that is replicable. Enterprises conforming to these standards have developed strong mechanisms that eliminate the risk of inconsistencies which might lead to premature breakdowns.

How to Conduct a Cost-Benefit Analysis Without Compromising Gear Quality?

A wise material selection approach is to look beyond the initial cost of the material to the overall cost of ownership, which includes the complexity of machining, cost of heat treatment, expected life, and any possible maintenance costs.

1. Calculating Total Cost of Ownership

TCO (Total Cost of Ownership) analysis considers various costs associated with the material over and above the material price. For instance, while steel is cheaper than other alloys, frequently replacing steel gears will cost more in the long run compared to using a costly higher, grade alloy that will last longer.

2. Value Engineering for Optimum Design

Value engineering is an approach that seeks to eliminate performance waste that is unnecessary. It is an approach that seeks to match the material perfectly with the application. For example, in the case of gears that are subjected to moderate loads, an ultra-high-strength alloy is overkill. It is better to use an alloy that is mid-grade and apply value engineering to the design to make sure that it is reliable.

3. Case Example: Long-Term Savings Analysis

Just consider a scenario where the carbon steel gear is initially more cost, effective but it only lasts 5, 000 hours thus necessitating replacements quite frequently. Whereas, an alloy steel gear, if subjected to the right heat, treatment, can easily give you a service of 15, 000 hours with hardly any maintenance required. Even if the alloy steel gear is pricier, it still ends up having a lower TCO due to the fact that the savings from fewer replacements and downtime more than make up for the higher initial cost.

Can Real-World Case Studies Demonstrate the Value of Scientific Material Selection?

Real-world case studies demonstrate the effectiveness of a scientific material selection approach in achieving success in the real world by applying theoretical concepts in a practical manner.

1. Case Background: Addressing Premature Failure

One of the leading manufacturers of construction equipment faced a continuous pitting problem on the gears made from 20CrMnTi material, with the gears lasting no more than 3000 hours.

2. Scientific Solution Implementation

The fail analysis and condition mapping indicated that the remedy was changing the material to 18CrNiMo7, 6 carburizing steel and modifying the heat treatment processes. The newly chosen material possesses both good core toughness and surface hardness, which enables it to withstand the most severe impacts. Along with the optimized process, implementation of tighter in, process controls to guarantee the product consistency was done.

3. Measurable Outcomes and Benefits

The results showed that the gear life was increased to above 8,000 hours, with a 70% decrease in failure rates. This change not only reduced maintenance costs but also improved machine reliability, proving the value of data-driven decisions.

H2: What Are the Step-by-Step Actions to Implement the Scientific Material Selection Framework?

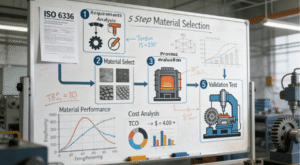

Applying the approach requires the execution of a systematic, five, step action plan that essentially transforms analysis into action thus, the project risks are lowered to a minimum.

- Define Requirement Specifications: Start by making a detailed list of requirements that covers all load, environmental, and life parameters. This requirements list is basically a checklist that guarantees no requirements are overlooked.

- Shortlist Candidate Materials: From the requirements, select 2-3 candidate materials that satisfy the key requirements. Data sheets and comparative charts are available that compare the performance of different materials with respect to one another, especially with regards to strength, hardness, and cost.

- Evaluate Manufacturing Feasibility: Then, the machinability and heat treatment necessities of the materials are checked.Manufacturing process evaluation is very important and includes the assessment of time, tool wear, and availability of equipment that can perform the process. One great thing is to get in touch with manufacturing specialists that can give an enlightening opinion about the possible problems that may be encountered during the process.

- Simulate Cost-Benefit Scenarios: Here, the TCO of all the materials will be simulated, considering their initial costs, processing costs, and lifespan. This will also enable the use of simulation techniques, which will aid in the visualization of the final outcome, thus creating a balanced approach for decision-making.

- Prototype and Validate: Finally, prototypes will be created for validation testing under accelerated conditions. Validation testing will verify the predictions made, and the process will be fine-tuned before proceeding into full-scale production. This process is of utmost importance for applications of high consequence.

Conclusion

Thus, the selection of the best possible material for use in custom gear machining services is a complex process. However, if the working conditions are assessed and the interaction of materials with the process is well understood, along with a detailed cost-benefit analysis, the performance-cost dilemma of materials can be overcome. This scientific approach will enable the creation of an optimized design, which will result in a product with performance, longevity, and cost-effectiveness.

FAQs

Q1: Is there professional advice on choosing materials for low, volume production runs?

A: Definitely, various well, known manufacturers provide engineering support for material selection, and a low, volume production run strategy will be considered in the choice of standard materials that are easily available to reduce cost and lead time, and through the supplier collaboration, the use of special heat treatments to attain the desired properties can also be considered.

Q2: How do we evaluate the feasibility of changing the material if we are not satisfied with the performance of our current gear material?

A: Initially, a failure analysis of the existing gears must be conducted, followed by defining new performance criteria. Afterward, the materials should be tested against the new criteria, and the assistance of the manufacturer can be sought for failure analysis and modeling.

Q3: What is the future outlook for new materials (such as composites) in gear applications, and how do they compare to traditional metals?

A: There are a couple of benefits from new materials such as composites, for example, they are lightweight and corrosion resistant in certain applications, but their load carrying capability and cost effectiveness are still significantly lower when compared with traditional metals. Generally, metallic alloys continue to be the predominant materials for heavy industrial applications, while new materials are utilized for niche markets only.

Q4: Apart from the basic material, what else is essential for the final life of a gear in service?

A: Besides the main material, there are a number of factors which are essential such as the absolute accuracy of the gear tooth profile, the exquisite manufacturing process, the uniformity of the heat treatment, the effectiveness of the lubrication system, and the correctness of installation alignment. Even the best material is powerless against design defects, inferior manufacturing, or unsuitable operating conditions.

Q5: How reliable are predictions of gear life using material information and simulation models?

A: Using current simulation models with precise load information and accurate material properties, predictions of gear life are quite reliable for comparison purposes and for detecting early signs of weakness. Nevertheless, prototype testing in real-life conditions is still the best method for final validation in high-stakes applications.

Author Bio

The author is a precision manufacturing specialist at LS Manufacturing. The company supports engineers and researchers in solving complex part challenges in the aerospace, medical, and automotive industries. The team maintains the highest quality standards through advanced technologies by combining their skills with the certifications IATF 16949 and AS9100D. For additional information, you may get in touch with them and avail yourself of a free, no, obligation project review and DFM analysis. Switch your idea into a cost, effective product.

Gernal

How Online CNC Turning Services Achieve 30% Cost Savings Without Compromising Speed or Quality

Introduction

In today’s competitive market, product development teams and procurement engineers face a common problem: pay a high premium to achieve rapid delivery or wait long production cycles to save costs. Communication challenges and unclear quoting mechanisms in traditional manufacturing processes only make project timelines and budget risks more complicated. The underlying reason for this problem, however, is that traditional supply chains are inherently inefficient and lack transparency. Each step of the process, from initial inquiry to production, creates a possible delay and uncertainty, making it very difficult to plan a project.

This article will explore the concept of professional online CNC Machining Services, including how it helps to achieve acceleration and cost reduction in manufacturing while maintaining precision quality. So, what’s the magic behind online CNC turning services? The answer to that question can be broken down into five important areas.

How to choose a reliable online CNC turning service to ensure part quality?

Selecting a partner for CNC turning services requires a careful evaluation of several core competencies to guarantee the quality of the final components.

Technical and Equipment Capabilities

The starting point of quality is advanced technology. A quality service provider is one that has the latest technology, such as multi-axis turning centers, which help in the manufacture of complex shapes with precision. Another important factor is the expertise of the technical staff who are capable of programming the process in order to handle different types of materials.

Systematic Quality Assurance

Quality is not something that occurs by chance. Reliable service providers are typically ones that have quality certification, which is a measure of their professionalism and a guarantee of a system that is capable of producing quality products such as CNC Precision Turning

l General Quality Management

ISO 9001 certifications show that there is a standard quality management system in place for all processes, including design, production, and service.

l Industry-Specific Certifications

In high-quality industries like the automotive industry, which requires reliability, traceability, and safety, industry-specific certifications like IATF 16949 or AS9100D show that the quality management system is up to high standards.

Digital Transparency and Value Assessment

Professional online manufacturing platforms use instant quoting systems to create transparency about price and manufacturability analysis, which is usually lacking in traditional methods. One common mistake to avoid is choosing the manufacturing partner solely on the basis of price. The cost associated with compromised quality, lack of technical support, and an unreliable supply chain is usually much higher in the long term compared to the cost savings. A comprehensive platform like the CNC turning services offered by JS Precision is an example of an integrated approach to manufacturing.

Where are the key quality control points for precision turned components?

The manufacture of precision turned components of high standard is a process where quality control plays a pivotal role at various steps. The basic parameters of the process, such as cutting speed, feed rate, and tool material, have a direct effect on the surface finish, accuracy, and geometric tolerance of CNC Precision Turning Parts. A slight deviation in these parameters can cause problems such as chatter marks, burrs, or dimensional errors.

The problem is more acute in the precision turning of steel components. Various types of steel (free-cutting steel, alloy steel, and stainless steel) require different tool materials, cooling systems, and cutting parameters based on differences in hardness, thermal conductivity, and work hardening properties. For example, turning stainless steel requires efficient heat removal to avoid deformation of the material and prolong tool life.

Precision inspection is the quality watchdog. Sophisticated inspection tools such as Coordinate Measuring Machines (CMMs) and optical comparators are necessary for inspecting components against CAD designs to check micron-level accuracy. Data-driven inspection, along with Statistical Process Control (SPC) techniques recommended by recognized institutions such as the Society of Manufacturing Engineers (SME), plays a vital role in maintaining consistency in batch production.

How does the CNC turning process adapt to the entire workflow from prototyping to mass production?

The CNC turning process is exceptionally well-suited to the entire product lifecycle, from concept to market, owing to its flexibility and consistency.

From Digital Design to Physical Prototype and Beyond

A basic CNC turning process begins with a CAD file, which is converted to machine instructions with the help of CAM software. This digital nature makes it an ideal tool for the iterative philosophy that any Rapid Prototyping Guide advocates, allowing designers to create physical prototypes in mere days. The process continues to a detailed engineering phase where professional teams analyze and optimize it further.

l Design for Manufacturability (DFM) Analysis

In this phase, professional engineering teams undertake Design for Manufacturability (DFM) analysis, offering suggestions to further improve the product’s strength, simplify it, or even make it less expensive. For instance, even a small change to a design for CNC Precision Turning Parts could result in considerable time savings or even eliminate the need to create special tools.

Access to Technical Expertise and Case Studies

Readers can explore specific technical details and real-world machining cases by reviewing this resource on CNC Precision Turning Parts, which provides deep insights into the application of these principles.

Seamless Scaling for Volume Production

After the prototype has been validated, the benefits of custom CNC turning services will become even more clear. With validated programs, optimized fixtures, and optimized processes, suppliers can scale production from a prototype to hundreds or thousands of units. This seamless scaling ensures quality throughout the life cycle of the product without having to go through the qualification process again with a new supplier.

How does the online on-demand production model reduce costs and increase efficiency for enterprises?

The on-demand part production model, enabled by advanced online manufacturing solutions, fundamentally reshapes corporate supply chains and cost structures. Primarily, it drastically reduces inventory carrying costs and capital investment risks. Companies no longer need to stockpile parts for forecasted demand, converting “inventory” into “in-transit goods” and freeing up significant cash flow.

Secondly, online manufacturing platforms streamline the traditionally lengthy and inefficient multi-step process (finding suppliers, requesting quotes, technical communication, order tracking) into a few simple steps for the user. Uploading drawings, receiving instant quotes, placing orders online, and tracking production progress—this digital workflow drastically reduces communication costs and human error, allowing procurement staff to focus on more strategic tasks.

According to reports from industry associations like the European Committee for the Co-operation of the Machine Tool Industries (CECIMO) on digital trends, this integrated and transparent supply chain is the future of manufacturing. A typical case study might show how a company consolidated its R&D department’s scattered part requests through an online platform. By leveraging the platform’s process optimization algorithms and bulk purchasing power, the company achieved an overall procurement cost reduction of approximately 30% while maintaining quality, and simultaneously reduced the average lead time by 40%, truly achieving the dual goal of cost reduction and efficiency improvement.

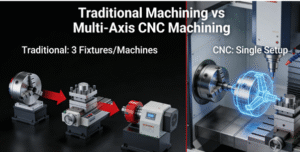

What solutions does multi-axis CNC turning technology offer for complex parts?

For complex geometries, conventional turning methods are not sufficient, and multi-axis CNC turning technology offers a revolutionary solution. Machines equipped with five-axis simultaneous movement capability enable turning, milling, drilling, and tapping operations in a single setup.

This complete-in-one-setup approach is a decisive advantage for machining complex precision turned components such as eccentric shafts or parts with complex contours. It not only eliminates the datum errors associated with multiple setups, ensuring extremely high geometric tolerances (like concentricity and perpendicularity), but also enables the production of single, integrated complex parts that would previously require multiple assemblies, thereby enhancing overall product strength and reliability.

Consequently, multi-axis technology significantly expands the capabilities of CNC Machining Services. It highly integrates what was once a lengthy, discrete CNC turning process, simplifying the workflow, shortening the total production cycle, and markedly reducing the cost and quality risks associated with process changeovers. It is a core technology in high-end precision manufacturing.

Conclusion

In a nutshell, it can be said that through the selection of online manufacturing services that possess superior technical capabilities and quality systems, it is possible to achieve full optimization in terms of speed, cost, and quality in the manufacturing of precision parts. By utilizing efficient digital platforms and superior CNC turning technology, it is definitely possible to achieve this goal. This not only helps to address current market challenges but is a significant step towards future intelligent manufacturing.

If you are looking to achieve a faster, more cost-effective, and efficient solution to your precision turned part needs for a critical project, it is highly advisable to upload your part drawings to a reputable online platform today and obtain an instant quote and manufacturability analysis to get started with optimizing your supply chain.

Author Biography

The article is penned by a precision manufacturing expert with more than 15 years of experience and is focused on sharing the latest in precision manufacturing technology and supply chain management expertise. His expertise has helped several of the world’s leading industrial technology companies. The information provided in this article is backed by the technical expertise of a precision manufacturing service provider.

FAQ Section

What is the general lead time for online CNC turning services?

A1: Generally speaking, the lead time will vary depending on the complexity of the part and the quantity of the parts to be produced. For moderately complex parts in standard materials, professional online CNC turning service providers can normally provide prototypes within a 3-7 day time frame and production within a 10-15 day time frame.

How is the dimensional accuracy of the turned parts, ordered online, ensured?

A2: Professional online CNC turning service providers will normally provide detailed quality inspection reports, often via Coordinate Measuring Machines (CMMs). It is important that the accuracy of the parts be specified in the online inquiry and that the inspection capabilities of the supplier match the specified tolerance ranges.

Do online platforms support CNC turning of various special materials?

A3: Yes, there are dozens of metal and engineering plastic materials available on the online platforms, ranging from stainless steel, aluminum, to PEEK, titanium, etc. The online platforms’ material libraries will normally provide information on the properties and application scenarios of the various materials for the user to select from.

How are situations usually dealt with if the received parts do not live up to expectations?

A4: Formal service providers have proper procedures for resolving quality disputes. As soon as a non-conformity is identified, communication with supporting inspection data should be started right away. Suppliers with certifications such as AS9100D usually have proper corrective and preventive action procedures to safeguard the rights of clients.

Is this model appropriate for low-volume, high-mix R&D requirements?

A5: It is very appropriate. One of the major benefits of the online on-demand production model is its flexibility in dealing with low-volume, high-variety production. It substantially lowers the startup cost per part, making it very appropriate for the R&D stage.

Gernal

Labarty: Hidden Gems and Off-the-Beaten-Path Spots

Nestled away from the bustling tourist trails, Labarty is a treasure waiting to be uncovered. This charming destination boasts stunning landscapes, rich culture, and warm-hearted locals who call it home. For those seeking an authentic experience beyond crowded attractions, Labarty offers hidden gems that promise unforgettable memories. Imagine wandering through quaint streets lined with artisanal shops or discovering breathtaking natural wonders that few have laid eyes on. Whether you’re a seasoned traveler or just looking for your next adventure, Labarty invites you to explore its secrets and embrace the thrill of venturing off the beaten path. Let’s dive into what makes this vibrant locale truly special!

The Beauty of Exploring Hidden Gems and Off-the-Beaten-Path Spots

There’s a unique thrill in discovering places that aren’t on everyone’s radar. Hidden gems breathe authenticity and charm, inviting you to connect with the locale in a deeper way.

When you wander off the beaten path, each turn reveals surprises. A secluded waterfall might beckon from behind thick foliage or an ancient stone structure stands quietly, steeped in stories waiting to be uncovered.

These experiences are often accompanied by fewer crowds. You can savor moments of solitude or engage more intimately with locals who share their traditions and insights freely.

Exploring less-traveled areas allows for genuine interactions. Conversations become meaningful as you learn about their lives and cultures without the filter of tourism.

In Labarty, these hidden treasures await your discovery—offering remarkable scenery and enriching encounters that form lasting memories.

Top 5 Hidden Gems in Labarty

Labarty is filled with surprises, just waiting to be uncovered.

First on the list is the enchanting Whispering Falls. This secluded waterfall offers a serene escape and perfect photo opportunities. The sound of cascading water soothes the soul.

Next, visit the quaint village of Carpencove. Known for its charming cottages and friendly locals, it’s an ideal spot to enjoy authentic crafts and handmade goods.

Don’t miss Secret Garden Alley. Tucked away between bustling shops, this floral haven bursts with color and fragrance—perfect for a quiet stroll or a moment of reflection.

For history buffs, Old Mill Ruins provide insights into Labarty’s past. With remnants from bygone days surrounded by lush nature, it tells stories that echo through time.

Venture to Moonlit Lake at dusk. The shimmering waters create a magical atmosphere where you can unwind under twinkling stars while listening to nature’s symphony.

Off-the-Beaten-Path Adventures in Labarty

Labarty is a treasure trove for those seeking adventure beyond the typical tourist trails. The rugged hills invite hikers to explore their hidden paths, where breathtaking views await at every corner.

Consider wandering through the dense forests that cradle secret waterfalls. These serene spots provide perfect picnic locations away from crowds.

For thrill-seekers, rock climbing along lesser-known cliffs offers both challenge and exhilaration. With fewer climbers around, you can enjoy nature in its most unspoiled form.

Kayaking on Labarty’s tranquil lakes presents another unique experience. Paddle across glassy waters surrounded by stunning landscapes, where wildlife makes unexpected appearances.

Remember to bring your camera; these adventures will create unforgettable memories against picturesque backdrops that few have seen. Embrace spontaneity as you uncover Labarty’s hidden wonders waiting just off the beaten path.

Local Cuisine and Culture in Labarty

Labarty’s local cuisine is a delightful reflection of its rich cultural tapestry. Here, tradition meets innovation in every bite. You’ll find dishes that blend flavors from various regions, showcasing the area’s culinary diversity.

Street vendors serve up tantalizing snacks, like spiced pastries and grilled meats. These are not just meals; they’re experiences steeped in history and community spirit.

Dining at family-owned restaurants offers an intimate glimpse into Labarty’s culture. Each dish tells a story—be it savory stews or fresh seafood caught right off the coast.

Local markets buzz with activity, where artisans showcase handmade goods alongside vibrant produce. The atmosphere is lively and inviting, making it easy to immerse yourself in everyday life here.

Festivals bring the streets alive with music, dance, and food stalls overflowing with regional specialties. It’s an opportunity to celebrate local traditions while savoring unique flavors you won’t find anywhere else.

How to Plan Your Trip to Labarty

Planning a trip to Labarty can be an exciting adventure. Start by determining the best time to visit. The weather varies, so check local forecasts for optimal conditions.

Next, create a rough itinerary. Identify the hidden gems you want to explore and allocate time accordingly. Research transportation options; renting a bike or using public transport can enhance your experience.

Accommodations in Labarty range from quaint guesthouses to charming hotels. Book early, especially during peak seasons, for better choices and prices.

Don’t forget essential travel items: comfortable shoes for wandering and a camera for capturing stunning sights.

Keep an eye on local events happening during your stay. Festivals or markets can provide unique insights into Labarty’s vibrant culture and community life while enriching your overall experience.

Conclusion

As you set out to explore Labarty, you’re bound to uncover the charm and allure that lie beyond the typical tourist spots. The joy of discovering hidden gems adds a unique flavor to your travels, allowing for authentic experiences that you’ll cherish long after your visit. From breathtaking landscapes to local culture and cuisine, every corner of Labarty holds surprises waiting for you.

Planning your trip becomes an exciting adventure in itself. With careful research and a spirit of curiosity, you’ll find yourself immersed in the beauty and diversity this destination offers. Travel smartly—consider visiting during off-peak seasons for fewer crowds or engaging with local guides who can reveal lesser-known treasures.

Whether it’s wandering through quaint streets or savoring traditional dishes at family-run establishments, each moment spent in Labarty enriches your travel narrative. Embrace spontaneity; sometimes the best memories come from unexpected detours along the way.

So pack your bags and prepare for a journey filled with exploration, discovery, and unforgettable moments in Labarty—a place where hidden gems await those willing to seek them out!

Gernal

How Much Is Cost Segregation Study? A Practical Pricing Guide for Real Estate Owners

If you own income-producing real estate, you’ve probably heard that a cost segregation study can accelerate depreciation and unlock meaningful tax savings. But the very next question is usually the same: how much is a cost segregation study going to cost you, and what determines that price?

The short truth is that pricing isn’t one-size-fits-all. Fees vary based on property type, purchase price, documentation quality, and whether the provider performs a detailed engineering-based analysis or a lighter, template-style allocation. In this guide, we’ll break down the real cost drivers, typical price ranges, what you should expect in a deliverable, and how to judge whether your quote is actually “worth it,” including scenarios tied to Cost Segregation Primary Home Office Expense, where documentation and usage details can affect how confidently deductions are supported.

And if you want a fast, professional way to estimate potential savings before you commit, Cost Segregation Guys can help you pressure-test the numbers and understand whether your property is a strong candidate, without guesswork and without overcomplicating the process.

What a Cost Segregation Study Really Is (And Why Pricing Varies)

A cost segregation study is a detailed analysis that reclassifies components of a building into shorter-life asset categories (typically 5-, 7-, and 15-year property) rather than depreciating most of the structure over 27.5 years (residential rental) or 39 years (commercial). The goal is to legally accelerate depreciation deductions, often increasing deductions in early years and improving cash flow.

So why does pricing swing so widely? Because studies are not all built the same. The biggest difference is methodology:

- Engineering-based studies typically involve specialists reviewing construction details, performing calculations, and often conducting site inspections. These tend to be more defensible and more thorough.

- Desktop or estimate-based studies can be cheaper, but the support, documentation, and precision may vary significantly.

Typical Price Ranges: What Most Investors See

While every provider prices differently, most real estate owners fall into predictable bands. Here’s a realistic overview of what you may encounter:

1) Small residential rentals (1–4 units)

For smaller rental properties, study fees can be relatively modest, especially if the property is straightforward and documentation is strong.

- Typical range: a few thousand dollars

- Pricing is usually influenced by: square footage, building complexity, and whether an inspection is performed

2) Larger multifamily properties (5+ units)

Multifamily studies usually involve more systems, more common-area components, and more detailed allocations.

- Typical range: mid four figures to low five figures

- Cost drivers: number of buildings, amenities, and how much of the total basis needs detailed segmentation

3) Commercial properties (retail, office, industrial, hospitality)

Commercial studies can become more complex quickly: tenant improvements, specialized electrical, equipment pads, parking, site work, and more.

- Typical range: often in the five figures, depending on complexity

- Cost drivers: building systems, specialized use, and quality of construction data

4) Portfolios and multiple properties

Providers may offer bundle pricing or discounts, but the true cost depends on whether each asset requires separate modeling and documentation.

- Typical range: varies widely

- Cost drivers: volume, repeatability, and consistency of documentation

If your main concern is how much a cost segregation study is likely to cost for your property, the quickest route is a savings and feasibility review. Cost Segregation Guys can walk through property basics and help you understand whether you’re looking at a high-ROI case before you spend money on a full report.

The Real Cost Drivers (What You’re Actually Paying For)

To understand your quote, you need to understand the cost components behind it. Providers generally price based on the time, expertise, and documentation needed to produce a defensible reclassification.

Property type and complexity

A simple single-tenant building with minimal site work will generally cost less than a property with multiple tenants, high-end improvements, extensive paving, landscaping, or specialized systems.

Total depreciable basis (purchase price minus land)

A higher basis often means more potential categories to identify and more calculations to support allocations.

Documentation quality

If you have strong records, closing statements, appraisals, depreciation schedules, construction drawings, and invoices, your study can be faster, more accurate, and sometimes less costly.

If records are missing, the team may have to recreate estimates using industry cost data, which adds time.

Site inspection requirements

Some firms include inspections by default; others treat it as optional. Inspection increases cost but can improve accuracy and defensibility.

Timeline and urgency

Rush delivery often increases fees, especially for complex properties.

Experience and defensibility

Not all providers deliver the same level of support. A study that’s built to be defendable, clear methodology, workpapers, detailed asset breakdowns, often costs more than a simplified allocation.

Engineering-Based vs. “Budget” Studies: Why the Cheapest Option Can Be Expensive

A low quote can look attractive until you consider what happens if the study lacks detail, support, or consistency with IRS expectations.

Cheaper studies may include:

- broad-brush allocations

- minimal narrative support

- limited documentation

- fewer line items and less traceability

More thorough studies typically include:

- a clear methodology section

- detailed asset-by-asset breakdowns

- site and land improvement analysis

- support schedules and workpapers

The point isn’t that every property needs the most expensive option; it’s that you should match the study to your risk tolerance, tax position, and the size of the depreciation benefit.

What Should Be Included in a Quality Study Deliverable

Regardless of price, your report should be usable by your tax preparer and defensible in its logic. At a minimum, look for:

- Property overview and assumptions (placed-in-service date, basis, land allocation approach)

- Detailed classification schedule (5-, 7-, 15-year components, and remaining 27.5/39-year)

- Site improvements breakdown (paving, landscaping, fencing, signage, drainage, lighting)

- Methodology narrative describing how costs were derived and allocated

- Supporting documentation or workpapers that tie numbers back to sources

- Depreciation schedules that your CPA can apply to your return

If a provider can’t clearly explain what’s included, treat that as a red flag, because the report’s value is tied to its clarity and support.

Bonus Depreciation and Timing: How Cost Interacts With Value

Many investors care about timing because accelerated depreciation is often most powerful when you can take larger deductions earlier. Bonus depreciation rules have changed over time, and your placed-in-service year can materially affect outcomes.

Even when bonus depreciation isn’t at peak levels, cost segregation can still front-load depreciation and improve cash flow, especially for owners with significant taxable income.

This is one reason feasibility analysis matters: the “right” time to do a study depends on the property’s basis, your tax bracket, passive activity limitations, and overall strategy.

Special Situations That Affect Pricing

Some scenarios can raise the complexity (and cost) of the study, but they can also increase the potential benefit.

Renovations and improvements

If you’ve done major improvements, a study may need to incorporate new assets, partial dispositions, or component changes. This takes extra analysis.

Cost segregation for short-term rentals or mixed-use

Properties with mixed personal and business use require careful treatment. The allocation must match actual business use, and records become more important.

Home office considerations

Some owners ask about how depreciation interacts with home office claims, especially if a portion of the property qualifies for business use. While a cost segregation study is typically used for investment or business property, the idea of properly classifying and supporting expenses often comes up in related planning, including Cost Segregation Primary Home Office Expense discussions, where documentation and defensibility are equally important.

“How Much Does a Cost Segregation Cost” vs. “Is It Worth It?”

It’s easy to fixate on the fee. But the more useful question is whether the study generates a strong return.

You may hear people ask, How Much Does a Cost Segregation Cost as if there’s a universal price tag. In reality, the better framework is:

- What is the likely accelerated depreciation benefit?

- What is my marginal tax rate and ability to use deductions?

- What is the cost of the study relative to expected savings?

- What is my documentation and audit-risk comfort level?

When these align, the fee often becomes a small portion of the value created.

Common Pricing Models You’ll Encounter

Providers typically use one of these pricing structures:

Fixed fee (most common)

A flat price based on property attributes and scope. This is easy to compare if the scopes are truly comparable.

Tiered pricing

A firm may price based on basis bands (e.g., up to X basis, X to Y basis, etc.), sometimes with add-ons for inspections or complex site work.

Contingent or “success-based” pricing

Some firms charge based on tax savings or depreciation identified. Be cautious: this can create incentives to be aggressive. Always understand the methodology and what support you’ll receive.

Hybrid

A base fee plus add-ons for additional buildings, improvements, or rush delivery.

Red Flags That a Quote May Not Be Comparable

Two quotes might look very different because they are not pricing the same deliverable. Watch for:

- vague scope language (“standard cost seg” with no detail)

- No mention of site work analysis

- No inspection option or unclear documentation requirements

- unclear workpaper support

- “guaranteed savings” language without explanation

A good provider can explain exactly what they do, why they do it, and how the numbers are built.

How to Lower the Cost (Without Lowering Quality)

You can’t always reduce pricing, but you can make the process more efficient, and sometimes that affects cost.

Here’s how:

- Gather documents early: closing statement, depreciation schedule, appraisal, prior returns, and improvement invoices

- Provide clear property details: square footage, unit count, construction year, renovations, and site work features

- Avoid rush timelines: scheduling inspections and analysis with a reasonable lead time reduces premium charges

- Bundle properties if appropriate: Portfolio pricing can help when multiple assets have similar profiles

The better prepared you are, the less time the provider spends recreating missing data.

FAQs Investors Ask Before Paying for a Study

Is a cost segregation study only for large properties?

No. Smaller properties can still benefit depending on the basis, tax bracket, and ability to use losses. But the fee-to-benefit ratio matters more at lower bases.

Can my CPA do it?

Some CPAs coordinate studies, but many outsource the engineering analysis to specialists. The key is experience and defensible methodology.

Do I need a site visit?

Not always, but it can improve accuracy, especially if documentation is limited or the property has significant site improvements.

Does the study cost deductible?

Often, the cost is treated as a professional fee associated with the property’s business/investment activities. Your CPA should confirm the correct treatment for your situation.

Conclusion

So, how much does cost segregation study cost? It depends on the property, the scope, and the methodology behind the report. You can find lower-cost options, but the value of a study is tied to how well it’s built, how clearly it’s documented, and how confidently your tax team can use it.

The smartest move is to compare quotes based on deliverables, not just the number at the bottom. If you want a straightforward way to evaluate your expected ROI and avoid paying for a study that doesn’t match your needs, Cost Segregation Guys can help you validate the opportunity, understand your pricing range, and move forward with confidence.

-

How to5 months ago

How to5 months agoHow to Get My Instagram Password on Android

-

Social Media5 months ago

Social Media5 months agoGo Viral Overnight: Proven Instagram Power Moves to Beat the Algorithm

-

Technology3 months ago

Technology3 months agoThe Importance of User Feedback Loops in AI Slide Builders

-

Social Media5 months ago

Social Media5 months agoGoing Viral in the Digital Age: Meaning, Importance, and Practical Tips

-

Social Media5 months ago

Social Media5 months ago7 Powerful Tips to Reach More People on Facebook (Without Spending a Fortune)

-

How to5 months ago

How to5 months agoHow to Turn Instagram Followers into Real Customers

-

Viral Tips1 year ago

Make Money Online from Home 2024

-

How to5 months ago

How to5 months agoViral Tips Online – How to Blow Up on TikTok Fast